- Home

- Product

-

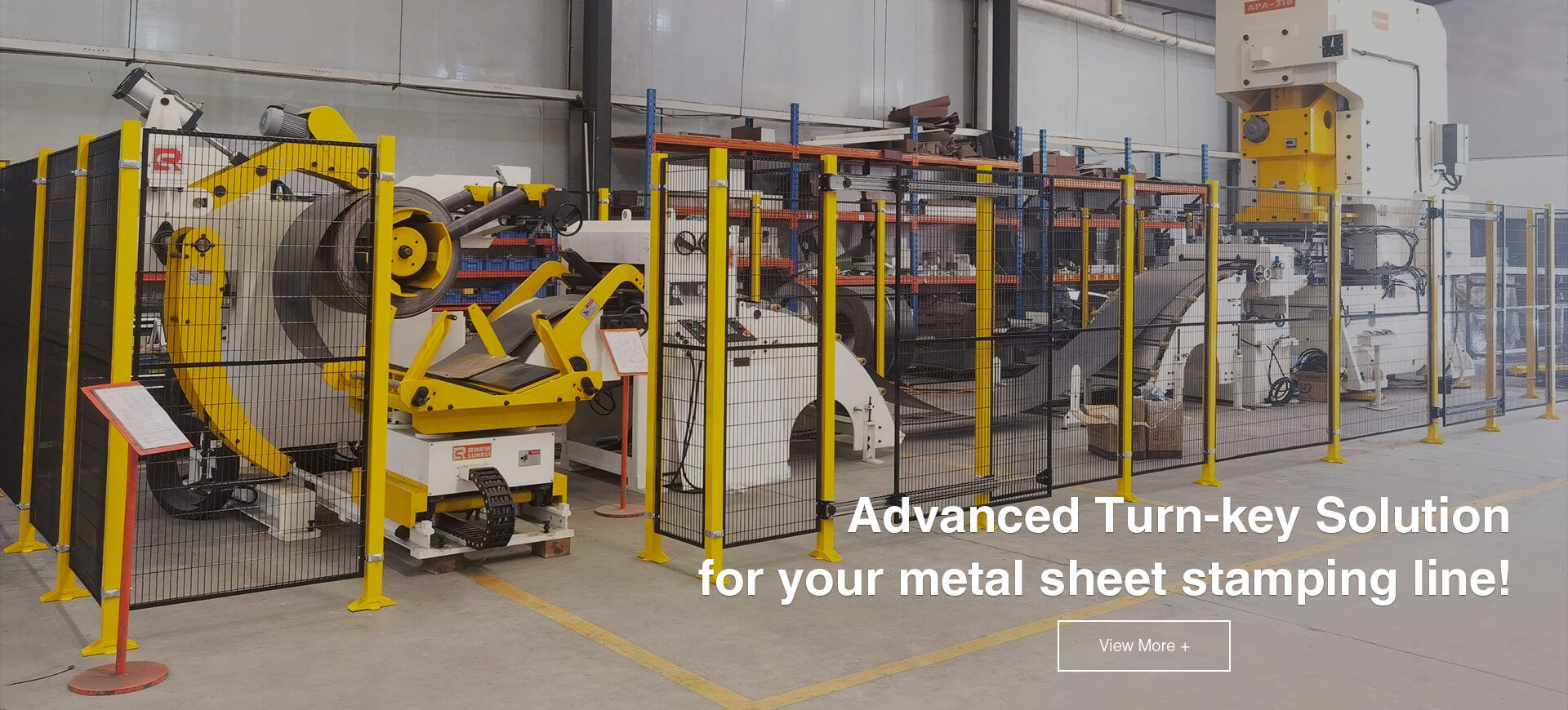

Solution

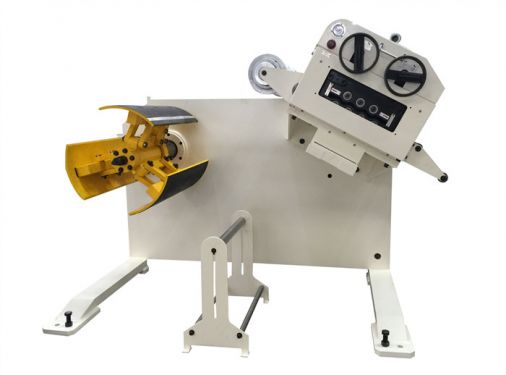

- Simple Press Stamping Line

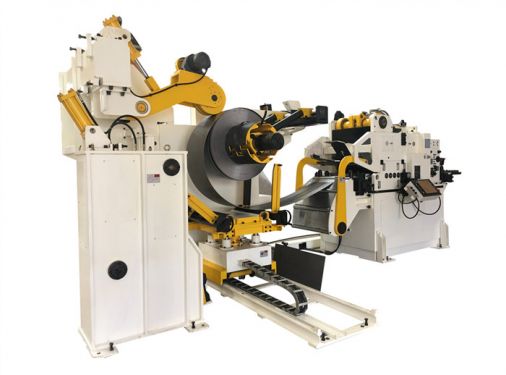

- Precision Pressfeed Stamping Line

- Coil Processing & Feed Lines

- Compact Coil Processing Line

- Full Function Coil Processing Line

- Coil Press Blanking Line

- Coil Feed Laser Blanking Line

- Multi-Blanking and Cut to Length Lines

- Circle Blanking Coil Processing Line

- High Speed Press Line

- High Speed Gripper Feed line

- High Speed Lamination Stamping Line

- 3 Axis Transfer System With Coil Feed Line

- Coil feed line with Press Transfer System for Auto stamping line

- Destacker and 3D transfer system with coil feed line

- Application

- Case

- About Us

- Service

- Contact Us