High Speed Press Line

Applicable material

Raw material: Brass, Copper, Stainless Steel, Iron

Material Thickness: 0.1-1.6m

Coil width: 20-200mm

High Speed Feed Lines configuration

Pallet Decoiler FU

High Speed Roll feeder RF

High Speed Press Machine RC

Progressive(For optional)

Unwinder machine(For optional)

Features of High Speed Press Line

1. For long devolpment, it can save materials and provide the production effection.

2. Equipped with C frame high speed mechanical press machine. The high speed penumatic punching machine capacity is 200-900/min. The minimun output per min is 600pcs. Half time will be saved during the operation. This type is more efficient and easier operated.

3. Our high speed press machine equiped the dynamic balancing device, it can make the machine steady when it works and prolong the service life of equipment.

What's more, we add the water tank, it can protect the mould . The function of water tank is cooling the mould and reduce the wastage of the mould.

4. We helped one of Bangladesh client to build up a new metal button company who bought 8 set of high speed production lines, 65 sets of moulds and 23 sets of assembly machine. So we do have capacity to give you the best machine and best service.

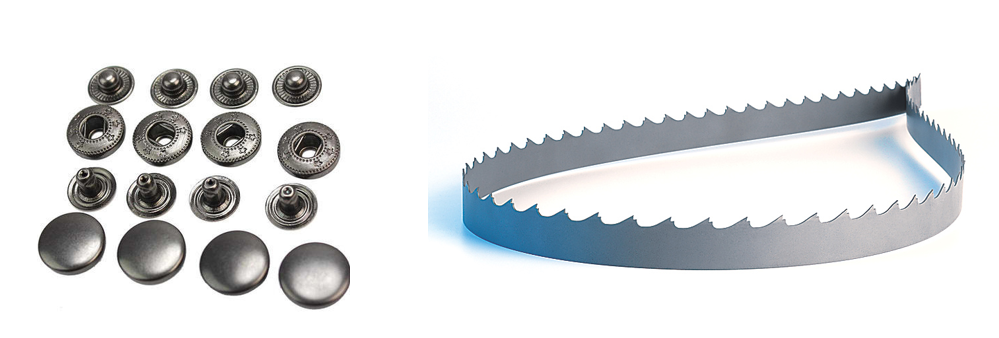

Stamped Parts

Main Machines Of High Speed Press Line

Pallet Decoiler FU

1. Pallet Decoiler is suitable for various kinds of metal sheet coil with thin thickness, such as brass, coopper, stainless steel, iron and so on.

2. Our pallet decoiler machine is made by welded steel which is capable of 4 or 5 coils at the same time and it can save coil changing time.

3. The speed is 0-24m/min, with inverter for speed control.

High Speed Roll feeder RF

1. High precision:+/-0.1mm

2. High speed: 600SPM

3. Suitable for material thickness :0-3.5 mm.

4.Suitable for all kinds of metal coil automatic feeding,easy to operate.

5.No power,High quality ,lowest maintenance.

High speed press machine RC

1. Manufactured from high tensile casting iron, stress relieved for Max. rigidity and long term accuracy. It's the best continuous production.

2. Double pillars and one plunger guide structure, manufactured from copper bush instead of the traditional board for minimize friction.

3. Working with forced lubrication to minimize thermal strain life of the frame,upgrade stamping quality and extend service life of the machine.

4. Balance device to reduce vibration, make the high speed press machine more stable and precision.

5. Adjust die manually with die height indicator and hydraulic clamping unit for die lock, it's very easy to fix and adjust it.

6. HMI is controlled by micro-computer, display value and fault monitoring system, it's easy to operate it.

Video