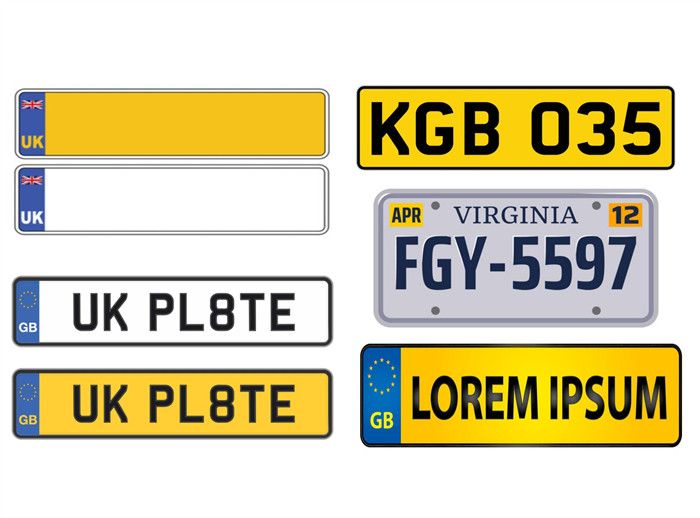

Car License Plate Stamping Line---An Overview of Technology and Processes

License plates serve as a vehicle's identification card, providing essential information such as the vehicle's registration number, state of origin, and sometimes even the vehicle owner's details. They play a crucial role in law enforcement, taxation, and vehicle tracking. Therefore, the manufacturing process must adhere to stringent quality standards to ensure durability and legibility.

Components of a License Plate Stamping Line

A typical automotive license plate stamping line consists of several key components, each playing a crucial role in the efficient production of high-quality license plates:

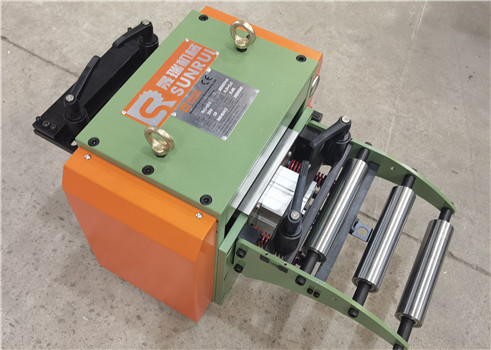

Uncoiler straightener system

An uncoiler straightener is an essential piece of equipment in metal processing and fabrication. Its primary function is to unwind coiled material, such as steel or aluminum, and to straighten it for further processing.

The operation begins with the uncoiler, which carefully unwinds the coil, ensuring that the material is fed smoothly without causing any damage or deformation.

Once the coil is unwound, the straightening mechanism takes over. This process involves passing the material through a series of rollers or plates that apply force to eliminate any bends or twists in the metal, resulting in a flat and even strip. In many cases, the raw materials may be protected by a layer of protective film to prevent scratches and corrosion during storage and transport.

Fortunately, the uncoiler straightener is designed to handle this situation effectively. As the material is unwound and straightened, the equipment can be equipped with mechanisms to remove the protective film. This is typically achieved through a combination of tension and shear forces that peel away the film without damaging the underlying material.

Once the material has been properly straightened and any protective film has been removed, it is then fed into a feeding machine. This machine will guide the material into the next stage of the manufacturing process, ensuring that it is positioned accurately for cutting, punching, or other operations.

Overall, the uncoiler straightener plays a crucial role in enhancing productivity and ensuring the quality of the final product by providing a reliable method for handling coiled materials while also managing protective coverings effectively.

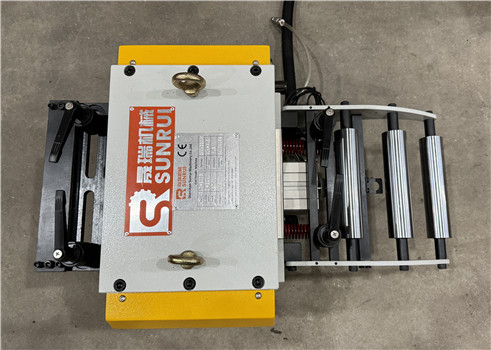

Feeding System:

The process begins with a metal coil or sheet feeder that supplies the raw material, typically aluminum or steel, to the stamping line. The feeding system must ensure precise alignment and consistent material flow. Advanced feeding systems may incorporate sensors and automation to monitor material levels and adjust feeding rates, minimizing waste and downtime.

Stamping Press :

The heart of the stamping line is the stamping press, which employs a combination of dies and high pressure to shape the raw material into the desired license plate form. These presses can be hydraulic or mechanical, with the capability to produce multiple plates simultaneously, significantly optimizing production efficiency. The precision of the stamping process ensures that features such as mounting holes and embossed characters are accurately formed.

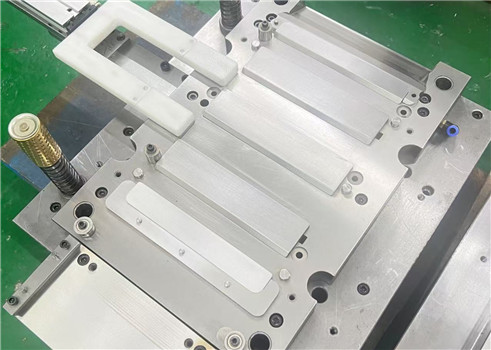

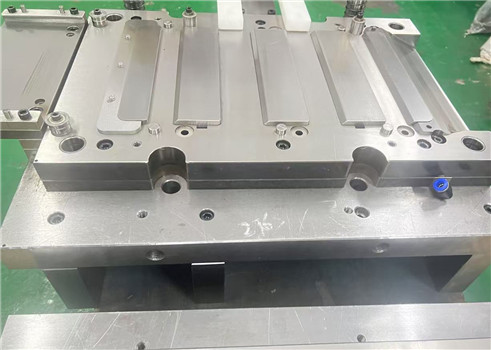

Progressive Die Sets:

Custom die sets are essential for creating the specific shapes and features of license plates, including cutouts, embossing for numbers and letters, and decorative elements.

High-precision dies are crucial for maintaining consistent quality and ensuring that each plate meets regulatory specifications. Manufacturers often use high-grade materials for die construction to withstand repeated use without significant wear.

Automatic Laminating Machine:

Following the stamping process, the plates are transferred to an Automatic Laminating Machine. This machine applies a protective layer that enhances the durability and longevity of the license plates. The laminating process involves the use of specialized films or coatings, such as vinyl or polycarbonate, which provide resistance against UV rays, moisture, and scratches. The automatic laminating machine is designed for high throughput and can handle various thicknesses and types of laminates. It often includes features such as:

Heat Activation: Some laminating processes utilize heat to activate adhesives, ensuring a strong bond between the laminate and the metal plate.

Roll-to-Roll Capability: This allows for continuous processing, increasing efficiency and minimizing production time.Quality Control Sensors: Integrated sensors monitor the lamination process to detect any issues, such as air bubbles or misalignment, ensuring that every plate meets quality standards.

Printing and Embossing:The next step involves printing or embossing the license plate with required information, including registration numbers, state designs, and any other relevant identifiers. Advanced digital printing technology allows for high-resolution graphics and customization options, while traditional screen printing remains a viable method for mass production. Embossing adds a tactile dimension to the plates, making them more visually appealing and enhancing their visibility.

Quality Control System:To ensure that each license plate meets regulatory standards, a comprehensive quality control system is integrated into the production line. This system conducts inspections at various stages, checking for: Dimensional Accuracy: Measurements are taken to ensure that each plate complies with industry standards.Surface Quality: Visual inspections and automated scanning detect defects such as scratches, dents, or imperfections in the laminate.Print Accuracy: Automated systems verify the clarity and correctness of printed information, reducing the likelihood of errors. Packaging and Distribution:Once the license plates are manufactured and pass quality inspections, they are packaged for distribution to dealerships, government agencies, or directly to consumers. Efficient packaging systems are designed to minimize damage during transit, often utilizing custom inserts or protective materials to ensure that plates arrive in perfect condition. Automated packaging solutions can also streamline this process, reducing labor costs and increasing throughput.

Conclusion

The automotive license plate stamping line is a complex assembly of advanced machinery and processes that work together to produce high-quality license plates that meet both consumer and regulatory demands. With advancements in technology, including automation and smart manufacturing practices, the efficiency and quality of production continue to improve. The integration of an automatic laminating machine not only enhances the durability of the plates but also allows for customization options that cater to diverse consumer preferences. As the automotive industry evolves, staying abreast of these advancements is essential for manufacturers looking to remain competitive and environmentally responsible.

This version provides a more in-depth exploration of each component, especially the automatic laminating machine, and emphasizes its importance in the production process. Let me know if you need any further adjustments or additional information!