Decoiler Straigtener for Producing Hardware Stamping Parts

SUNRUI MACHINE proposed a Decoiler Straightener system to flatten the master coils before running them through the stamping die. The system aided in material straightening and resulted in a consistent thickness necessary for accurate stamping.

The Decoiler Straightener was custom-made to suit the specific needs of the manufacturer and fit seamlessly into the existing production line. The system was highly efficient, with quick setup time and easy adjustment for different material thicknesses.

Decoiler Straigtener for Producing Hardware Stamping Parts To Spain

SUNRUI MACHINE proposed a Decoiler Straightener system to flatten the master coils before running them through the stamping die. The system aided in material straightening and resulted in a consistent thickness necessary for accurate stamping.

The Decoiler Straightener was custom-made to suit the specific needs of the manufacturer and fit seamlessly into the existing production line. The system was highly efficient, with quick setup time and easy adjustment for different material thicknesses.

What's The Decoiler straightener?

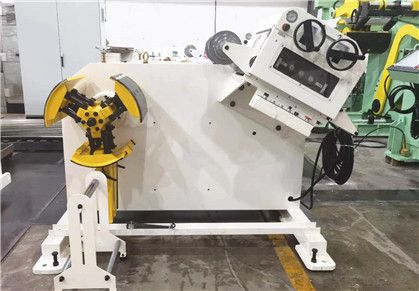

Decoiler straightener is a type of machine used to process coiled metal materials. The machine unrolls the coil and feeds the material through a series of rollers, which straighten and flatten it, providing a continuous, even feed to downstream machines such as feeders, presses, or stampers.

The SUNRUI Decoiler Straightener combines both functions. It is a compact, user-friendly machine that can straighten and remove material loop from the coiled sheet at the same time, effectively reducing labor and transportation costs. The machine features advanced electric and hydraulic systems, ensuring high-precision operation and minimal maintenance.

What's Advantages of SUNRUI Decoiler Straightener?

1. High Precision: The machine's advanced control system provides high accuracy and precision, ensuring consistent, uniform processing of materials.

2. Efficient Operation: The machine's quick-change design allows for easy switching between different materials and thicknesses, reducing downtime and increasing efficiency.

3. Integrated Design: The machine combines both decoiling and straightening functions, reducing the need for additional equipment and streamlining the production process.

4. Compact Design: The machine's compact size and user-friendly operation make it easy to integrate into existing production lines.

5. Customization: SUNRUI Decoiler Straightener can be customized to meet specific customer needs, with a range of options available for material thickness, width, and processing speed.

How To Choose The SUItable Decoiler Straightener?

When choosing a suitable decoiler straightener, it is essential to consider the following factors:

1. Material Type and Thickness: The machine should be capable of processing the specific material type and thickness required for your application.

2. Coil Width and Inner Diameter: The machine should have the necessary capacity to handle the width and inner diameter of your material coil.

3. Production Volume: The machine's processing speed should match the required production volume to ensure efficient operation.

4. Customization Options: It is essential to choose a machine that can be customized to meet specific production needs and requirements.

5. Maintenance and Service: Choose a manufacturer that offers reliable after-sales service and support, ensuring minimal downtime and maximum productivity.

Overall, SUNRUI Decoiler Straightener is a reliable and user-friendly machine that offers high precision, efficiency, and customization options to meet specific production needs. The machine is suitable for use in a range of industries, including automotive, construction, and metalworking.