SUNRUI COIL FEED LINE: A Preferred Choice for Automotive Stamped Parts Manufacturers

Automotive stamped parts are essential components in the manufacturing of vehicles, playing a vital role in their structure and functionality. From brackets to end caps and dust covers to spring seats, these metal stamped parts are integral to vehicle assembly. In this article, we will explore the characteristics of automotive stamped parts, the production processes involved, and key design considerations, along with the benefits of advanced technologies like the SUNRUI COIL FEED LINE.

What Are Automotive Stamped Parts?

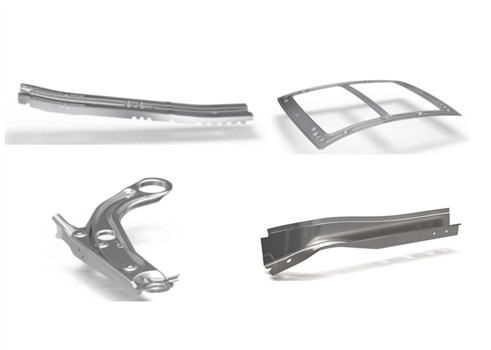

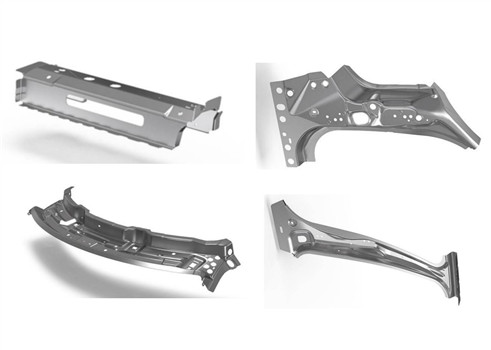

Automotive stamped parts are metal components produced through a stamping process, which involves shaping and cutting material, typically sheet metal, using specialized dies. These parts are characterized by their lightweight nature, excellent rigidity, and high strength, making them ideal for automotive applications. Common examples include:

Brackets: Used for structural support.

Spring Seats: Essential for holding springs in place.

End Caps: Often used to close off components.

Covers: Protect internal parts from dust and debris.

Compression Valve Covers: Integral to engine assembly.

Key Characteristics of Automotive Stamped Parts

Lightweight with High Rigidity and Strength: Automotive stamped parts are designed to be lightweight while maintaining structural integrity, which is crucial for vehicle performance and fuel efficiency.

Superior Surface Quality: The stamping process ensures that the material surface remains undamaged, leading to better final surface quality. Post-stamping, these parts can undergo surface treatments such as painting and electroplating, enhancing their aesthetics and resistance to corrosion.

High Dimensional Accuracy: These parts exhibit high dimensional precision, ensuring uniformity across components. This interchangeability is vital for standard assembly, facilitating efficient production processes.

Design Considerations for Automotive Stamped Parts

When designing automotive stamped parts, several factors need to be considered to ensure optimal performance and manufacturability:

Simplicity in Structure: A straightforward and reasonable structure is advisable. This helps minimize the number of processing surfaces and overall processing area, leading to cost reductions.

Material Selection: The materials used must meet both the technical requirements of the product design and the stamping process. They should also be compatible with subsequent processes like cutting, electroplating, and cleaning.

Formability Requirements: The material should possess excellent plasticity and a favorable thickness-to-width ratio to facilitate easy deformation during stamping. While good formability is essential for the forming process, it is less critical for the separation process.

The Role of SUNRUI COIL FEED LINE in Automotive Stamping

One of the leading solutions for automotive stamped parts manufacturers is the SUNRUI COIL FEED LINE. This advanced technology is designed to enhance the efficiency of the stamping process, ensuring that manufacturers can produce high-quality parts with precision and speed. The SUNRUI COIL FEED LINE offers several advantages, including:

Improved Material Handling: The system efficiently feeds materials into the stamping process, reducing wait times and increasing productivity.

Enhanced Precision: With advanced control mechanisms, the SUNRUI COIL FEED LINE ensures accurate feeding, which is critical for maintaining dimensional accuracy in stamped parts.

Cost-Effectiveness: By optimizing the production process, manufacturers can lower operational costs while achieving high-quality outputs.

Factors Affecting Precision in Automotive Stamped Parts

Precision requirements can vary significantly among different automotive stamped parts. Here are some key factors that influence the dimensional accuracy:

Mold Manufacturing Precision: The accuracy of the molds used in the stamping process significantly impacts the final dimensions of the parts.

Die Gap: The clearance between the upper and lower dies can affect how the material deforms and, consequently, the final dimensions.

Precision Levels in Automotive Stamped Parts

Automotive stamped parts can be categorized into precision grades: ordinary and precision grade. Ordinary grade parts can achieve acceptable precision using economical methods, while precision grade parts require more advanced stamping techniques. It's essential to ensure that the surface quality of stamped parts does not exceed that of the raw materials to avoid increased production costs due to additional processing.

Understanding automotive stamped parts is crucial for manufacturers striving to produce high-quality components that meet stringent industry standards. By focusing on design simplicity, material selection, and precision considerations, manufacturers can effectively meet customer expectations while maintaining cost efficiency. The incorporation of advanced technologies, such as the SUNRUI COIL FEED LINE, further enhances production capabilities, making it a preferred choice for automotive stamped parts manufacturers.

In summary, the automotive stamping industry continues to evolve, driven by advancements in technology and an increasing demand for high-quality, efficient production methods. By staying informed about these developments, manufacturers can better position themselves for success in the competitive automotive market.