The Advantages of SUNRUI MACHINERY's Coil Feed Line in the Automotive Manufacturing Industry

The automotive manufacturing industry demands precision, efficiency, and reliability in every stage of production. From body panels to chassis components, the quality of metal processing directly impacts the performance and safety of vehicles. SUNRUI MACHINERY, a leading manufacturer of coil processing equipment, offers state-of-the-art coil feed lines that are specifically designed to meet the rigorous demands of the automotive sector. In this blog, we'll explore the key advantages of SUNRUI MACHINER's coil feed lines and how they contribute to the success of automotive manufacturing processes.

What is a Coil Feed Line?

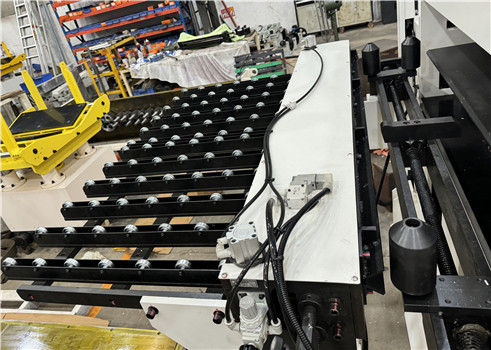

A coil feed line is an integrated system that typically includes a decoiler, straightener, and feeder. It is designed to efficiently process metal coils by unwinding, flattening, and feeding the material into downstream equipment such as stamping presses, laser cutters, or punching machines. In the automotive industry, coil feed lines are essential for producing high-quality metal parts with consistent precision.

Advantages of SUNRUI MACHINERY’s Coil Feed Line in Automotive Manufacturing

1. Precision and Consistency

Automotive parts require extremely tight tolerances to ensure proper fit and function. SUNRUI MACHINERY's coil feed lines are engineered with advanced servo-driven feeders and precision straighteners that deliver consistent material positioning and flatness. This level of accuracy is critical for producing components like door panels, hoods, and structural reinforcements, where even minor deviations can lead to assembly issues or compromised safety.

Servo Feeders: SUNRUI's servo-driven feeders offer unmatched precision, allowing for exact material advancement and repeatability.

Straightening Systems: Their straighteners ensure that metal sheets are perfectly flat, eliminating defects that could affect the final product.

2. High-Speed Production

The automotive industry operates on tight schedules, requiring manufacturers to produce large volumes of parts quickly. SUNRUI MACHINERY's coil feed lines are designed for high-speed operation, enabling manufacturers to meet production targets without sacrificing quality.

Efficient Decoiling: SUNRUI's decoilers are equipped with motorized systems that ensure smooth and rapid unwinding of coils.

Seamless Integration: Their coil feed lines are designed to work seamlessly with stamping presses and other downstream equipment, minimizing downtime and maximizing throughput.

3. Versatility for Diverse Materials

Automotive manufacturing involves processing a wide range of materials, from thin gauge steel to high-strength aluminum. SUNRUI MACHINERY's coil feed lines are highly versatile, capable of handling various material types, thicknesses, and widths. This flexibility is essential for producing different automotive components, such as lightweight aluminum body panels or durable steel frames.

Adjustable Systems: SUNRUI's equipment features adjustable rollers and tension controls to accommodate different materials.

Durability: Their machines are built to withstand the rigors of processing high-strength materials, ensuring long-term reliability.

4. Reduced Material Waste

In an industry where material costs are significant, minimizing waste is a top priority. SUNRUI MACHINERY's coil feed lines are designed to optimize material usage, reducing scrap and saving costs.

Precision Feeding: Accurate material advancement ensures that every inch of the coil is utilized effectively.

Advanced Straightening: By eliminating defects and imperfections, SUNRUI's straighteners reduce the need for rework or material rejection.

5. Enhanced Automation and Productivity

Automation is a cornerstone of modern automotive manufacturing. SUNRUI MACHINERY's coil feed lines are equipped with advanced automation features that streamline production processes and reduce the need for manual intervention.

Automated Coil Loading: SUNRUI's decoilers can be equipped with automatic coil loading systems, reducing labor requirements and improving safety.

User-Friendly Controls: Their equipment features intuitive control panels that allow operators to easily set up and monitor the production process.

6. Durability and Reliability

Automotive manufacturing environments are demanding, requiring equipment that can operate continuously without frequent breakdowns. SUNRUI MACHINERY's coil feed lines are built to last, with robust construction and high-quality components that ensure reliable performance even in the most challenging conditions.

Heavy-Duty Design: SUNRUI's machines are constructed from durable materials to withstand heavy use.

Low Maintenance: Their equipment is designed for easy maintenance, minimizing downtime and keeping production running smoothly.

7. Customization for Specific Needs

Every automotive manufacturer has unique requirements based on the types of parts they produce. SUNRUI MACHINERY offers customized coil feed line solutions tailored to the specific needs of their clients.

Tailored Configurations: SUNRUI works closely with customers to design coil feed lines that match their production requirements.

Scalable Solutions: Whether you're a small supplier or a large OEM, SUNRUI's equipment can be scaled to fit your operation.

Applications in the Automotive Industry

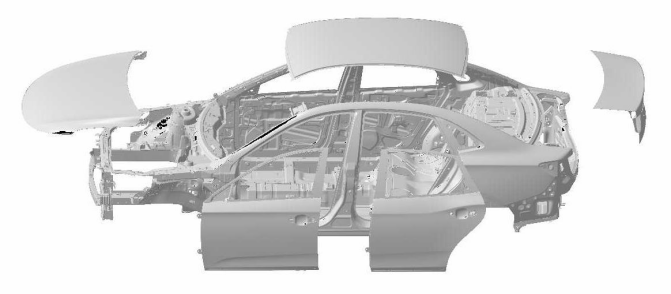

SUNRUI MACHINERY's coil feed lines are used in the production of a wide range of automotive components, including:

Body Panels: Doors, hoods, and fenders.

Structural Parts: Chassis components, cross members, and reinforcements.

Interior Components: Seat frames and brackets.

Lightweight Materials: Aluminum and high-strength steel parts for electric vehicles (EVs).

Why Choose SUNRUI MACHINERY?

SUNRUI MACHINERY has earned a reputation as a trusted partner in the automotive manufacturing industry. Their commitment to innovation, quality, and customer satisfaction sets them apart from competitors. By choosing SUNRUI’s coil feed lines, automotive manufacturers can:

Improve production efficiency and reduce costs.

Achieve consistent, high-quality results.

Stay competitive in a rapidly evolving industry.

Conclusion

In the fast-paced and demanding world of automotive manufacturing, SUNRUI MACHINERY’s coil feed lines offer a winning combination of precision, speed, versatility, and reliability. Their advanced equipment is designed to meet the unique challenges of the automotive sector, helping manufacturers produce high-quality parts efficiently and cost-effectively.

If you're looking to enhance your automotive production capabilities, consider SUNRUI MACHINERY's coil feed lines. With their expertise and cutting-edge technology, they can help you stay ahead in the competitive automotive industry. Contact SUNRUI MACHINERY today to learn more about their solutions and how they can benefit your operation. Drive your success with SUNRUI!

Decoiler Straightener Feeder 3 IN 1 for Auto Parts is Testing | Compact Coil Feed line