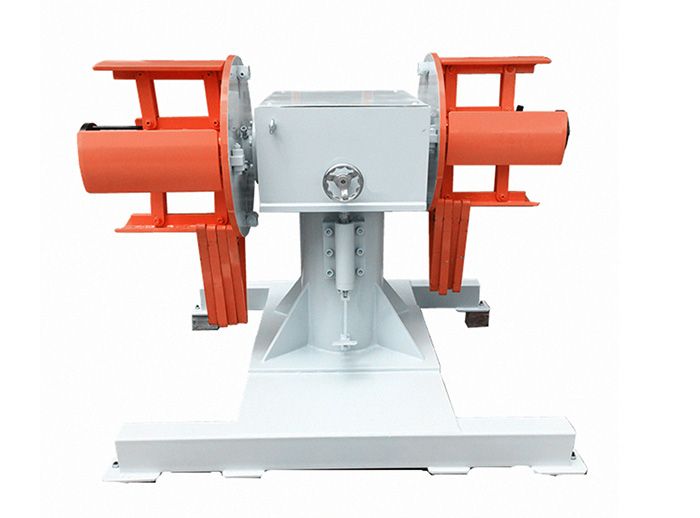

Decoiler

A decoiler machine is a type of equipment used to uncoil metal coils, which are typically used in manufacturing processes such as stamping, forming, and roll forming. The process of uncoiling involves unwinding the metal coil from a spool or reel, and then feeding it into a production line where the raw material is transformed into finished products.

Decoiler machines are commonly used in the metalworking and manufacturing industries because they help to simplify the coil handling process, reduce waste, and increase production efficiency. The machines are available in various configurations based on the type of material being uncoiled and the desired production specifications.

Some common features of decoiler machines include pneumatic or hydraulic tensioning systems, electronic or manual speed control mechanisms, and safety guards to ensure employee safety during operation. Decoiler machines may also be equipped with straightening systems or other accessories to further optimize the production process.

If you have any specific inquiries or would like to discuss winding processes further, please feel free to contact me anytime.

What is decoiler?

The decoiler is a special machine for uncoiling the coils. It is used to uncoiling the coils steel strips and lead the coils strips into leveling and feeding process. According to the relevant configuration, the decoiler is installed at the begining of production lines. It is suitable for machinery, vehicles, metal products home appliances, steel structure, decoration and other industries.

Uncoiler is one of the essential equipment in metal sheet stamping production line and roll forming line. The other one is to feed the steel strips into the leveling machine with the help of straightening machine rotation. Therefore, the performance of the uncoiler is very important for the whole production line. During the years of uncoiler design practice, the structure of the uncoiler is constantly optimized and improved, so that the performance of the uncoiler can be improved.

Welcome to contact decoiler manufacturer-Sunrui Machinery. We have hydraulic decoiler machine, manual decoiler machine, double head decoiler machine, double head hydraulic decoiler machine, pallet decoiler machine for sale!

Features of the decoiler

It is crucial to find a well-designed machine to provide stable and accurate processing under general production demands. Before deciding on the right decoiler, you should be aware that it.

Can take a wide range of materials even with certain limitations.

Compatibility with straighteners and feeders if they do not perform these functions (considering the maximum coil width).

The wide variation in the performance range of the correct load capacity.

Coil width (please note that thick materials require motorized models, while in other cases you can use manual uncoilers).

Double head decoiler also will be an option if you want to save the loading time.

Decoiler FAQ

Q: What is the capacity of your decoiler?

A: 0.5 ton, 0.8 ton, 1 ton, 1.5 ton, 2 ton, 3 ton, 5 ton, 6 ton, 10ton, 15ton, 20ton available.

Q: Can your coil uncoiler be customized?

A: We offer customized uncoiler. The capacity of the uncoiler, coil carriage, press arm, and support arm are optional.

Q: What are the features of your decoiler?

A: Our unwinders are CE certified. All electronic components are also CE certified. Parameters can be customized.

Q: Can I buy just the uncoiler?

A: You can also choose Feeder, Straightener and Coil Blanking Line.

Our decoiler types

We offer a wide range of decoilers for handling metal, paper, plastic on coils. Decoilers are typically used to clamp and unwind materials from coils of various weights and widths. Here, the coil holder is easily fixed inside. Some compact manual uncoilers are equipped with wheels and can therefore be moved around the site. But if a unit is large enough, it will be secured to the floor, depending on safety requirements. If it is electric, the uncoiler will be more expensive. Such a model can have several motors and a set of switches, such as forward, reverse, stop, and automatic overdrive. For a matching roll forming machine, a VFD drive is available as an option.

If you look for an decoiler for sale, you can reduce the cost by considering the equipment needed based on its power and options. Make sure you are aware of the special offers available on our website. We use safety control software to design safe and efficient equipment that will stop the operating process if the instructions are violated.