Decoiler Straightener GL (0.3-3.2mm)

Applicable Material

Raw Material Type: Hot-Rolled Metal steel, Cold-Rolled Metal steel, Galvanized Metal steel, Stainless Steel etc.

Coil Width: 100-600 mm

Material Thickness: 0.3-3.2 mm

Coil Weight: <3000kgs

Inner Diameter: 470-520mm

Outer Diameter: 1200mm

Working Speed: 16m/min

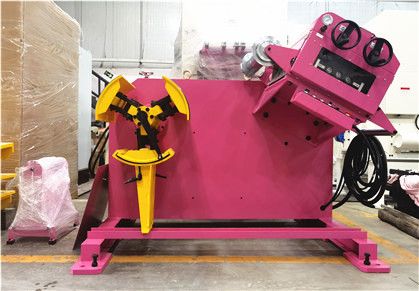

Brief Profile of Decoiler Straightener

The Decoiler Straightener is a machine used for material handling that performs two crucial functions, uncoiling steel strips from coils and leveling the material. It's commonly located at the beginning of a process line to hold and safely pay off or uncoil steel strips while straightening them. This machine is usually used in producing finished metal coils used for slitting, rolling, forming, and stamping applications.

Our Decoiler Straightener System is designed to maximize workshop space and increase operational safety. It can handle metal sheet coil strips of various sizes and thicknesses ranging from 100mm to 600mm in width and 0.3mm to 3.2mm in thickness with coil weights up to 3000kgs.

With precise upper and lower straightener rollers distance adjustment made by pneumatic pressure and worm gear adjustments, our Decoiler Straightener System can straighten and level metal sheet materials to meet the required standard. It is primarily used in the hardware stamping, electrical products, computer shell, and other similar industries.

Decoiler Straightener is an essential machine tool used in modern manufacturing and processing lines for high production efficiency, precision, and reliability.

Application of Decoiler Straightener

Decoiler straightener is the first beginning of the Metal sheet stamping line, it's used the loading the coils and straightening the metal sheet strips and leading the strips into the Mechanical Power Press and Coil Servo Feeder machine.

Decoiler straightener can be found in many different stamping product line such as hardware stamping line, saw blade stamping line, knives pressing line, motorcycle parts stamping line, car license plate stamping line, small auto parts stamping line, computer and electronic components stamping lines etc.

The configuration of metal sheet stamping line

Step-1: Decoiler straightener, Loading coil and uncoilling coil and straigthening the Coil strips.

Step-2: NC Servo Roll Feeder machine, Feed coil strips to press machine.

Step-3: Power pres machine with the progressive die, pressing to the end product.

Features of Decoiler Straightener

● There are 3 leaves on the mandrel for expansion.

● Pressing arm can be added according to specification.

● Japan magnetic contactor and electronic components prolong the service life;

● Frequency conversion speed control can be chose, the use effect is better.

● Leveler inclines appropriately to reduce feeding loop distance.

● Adopt one point down pressure device, exclusive design, can adjust the flat point more quickly and accurately, the operation is convenient, different from the traditional four point adjustment.

● Simple maintenance and management, good safety and low cost;

Specification of Decoiler Straightener

| Model | GL-200 | GL-300 | GL-400 | GL-500 | GL-600 |

| Max coil width | 200mm | 300mm | 400mm | 500mm | 600mm |

| Coil thickness | 0.3-3.2mm | ||||

| Coil inner diameter | 460-520mm | ||||

| Coil outer diameter | 1200mm | ||||

| Loading capacity | 800kg | 1000kg | 1500kg | 2000kg | 2000kg |

| Expansion style | Manual Expansion | ||||

| Straightener roller | Ø48mm*7pcs | ||||

| Uncoiler Motor | without | ||||

| Straightener Motor | 1HP | 1HP | 2HP | 2HP | 2HP |

| Roller pressing way | Pneumatic rod | ||||

| Roller adsjuting way | Eccentric turbine worm adjusting | ||||

| Inverter | Delta, Taiwan | ||||

| Feeding speed | 16m/min | ||||

| Pressing arm | Optional | ||||

Main Part of Decoiler Straightener

Decoiler Part

● The motor control cabinet of the material combined decoiler straightener are relatively independent, also they use their own frequency converter, that means it could take more effectively protecting the machine to make sure there will not distorted when it subjected to other external forces.

● The drive system of the straightening machine are universal joint and gear transmission, that could effectively avoid the material's damage from passive wheel rotation.

Straightening Part

● With pneumatic pressure on upper and lower straightener roller distance adjusting and worm gear adjusting, it can achieve precision straightening performance for many different kind of metal sheet material.

● The roller is made of solid bearing steel. After heat treatment, hard chrome plating and re-grinding, it has high hardness, good abrasion resistance and long use life.

● Roller leveling and feeding machine are placed on the same horizontal platform, which can reduce the feed machine and leveling error to meet the need of high precision.

● This type combo uncoiler straightener machine is very popular in European countries, if you want to know more about it, warmly welcome to email us, thanks!

● SUNRUI machine will help with the metal sheet stamping solutions!

Video of Decoiler Straightener