Manual Decoiler Machine

Applicable Material

Raw Material Type: Suitable for vary kind of coil material, such as Galvanized steel, Stainless steel, CR Steel, HR Steel, Galvanized steel, Stainless steel, Aluminum, Cooper etc.

Applicable Coil Width: 20mm-1300mm

Applicable Coil Thickness: 0.3-3.5mm

Coil Inner Diameter: 450-530mm

Coil Outer Diameter: 1200mm

Speed: 15m/min

Pressing arm and coil car for optional

Applications: Pressing Line/Metal Stamping Line/Forming Line

Brief Profile of Manual Decoiler Machine

Motorized Manual decoiler is design for the low weight metal coils uncoiling, it's located at the beginning of a process line used to hold and safely pay off or uncoil the steel strip,usually configured with the sheet metal straightener, NC servo feeder machine and power press machine.

Motorized Manual decoiler can uncoiler the coil strip from 70mm to 800mm width, from 0.2mm to 6mm thickness and load the weight up to 2tons. Usually it’s suible for the inner diameter 450-530mm, and outer diameter 1200mm.

What's more, if the thickness over the 3mm thickness, we suggest add the pressure arm to avoid injury the operator due to the excessive flexibility ofA Motorized Manual decoiler machine is a valuable tool located at the beginning of a process line, designed to safely and efficiently uncoil low weight metal coils. This machine is often configured with a sheet metal straightener, NC servo feeder machine, and power press machine to create a complete production line.

The Motorized Manual decoiler is capable of uncoiling steel strips with widths ranging from 70mm to 800mm, thicknesses varying from 0.2mm to 6mm, and a load capacity of up to 2 tons. It is typically suitable for coils with inner diameters between 450-530mm, and an outer diameter of up to 1200mm.

It's important to note that, to ensure operator safety while working with thicker materials above 3mm in thickness, a pressure arm can be added to the Motorized Manual decoiler. This feature enhances safety by reducing the possibility of injury resulting from the excessive flexibility of the material.

Overall, the Motorized Manual decoiler provides a reliable and effective solution for the safe uncoiling of low weight metal coils. This machine is a versatile and essential tool in production lines, as it improves efficiency and helps reduce the potential for injury, delivering high-quality results with every use.

Application of Manual Decoiler Machine

Decoiler machine is suitable for all kinds of metal sheet stamping, such as the hardware parts, home appliances, furniture hardware, motorcycle accessories, mobile phone accessories, computer accessories and so on.

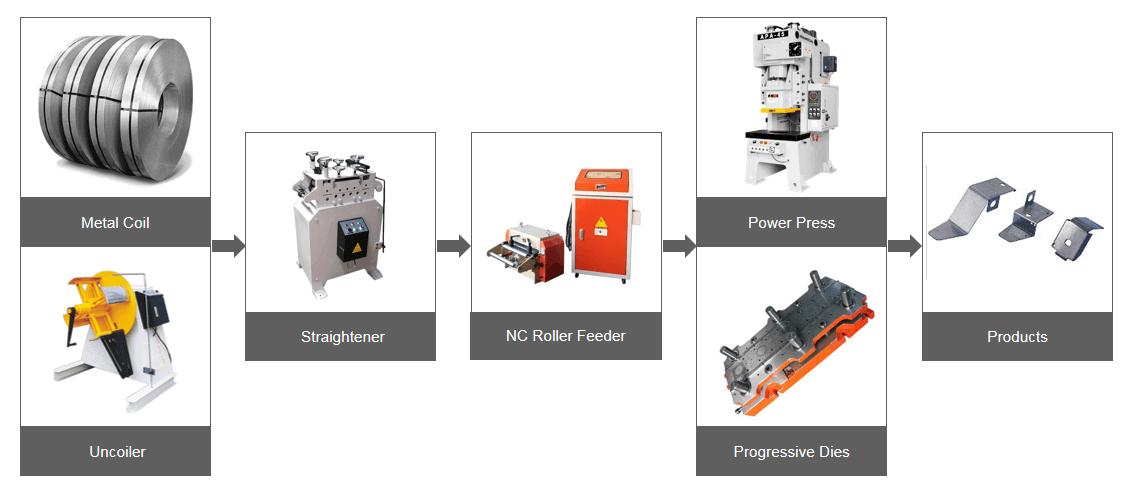

The configuration of metal sheet stamping line.

Step-1: Uncoiler machine, Loading coil and uncoilling coils

Step-2: Metal straightener machine, leveling the strips and lead it to feeder machine.

Step-3: Nc Servo Feeder machine, Feed coil to press machine.

Step-4: Power press machine with the moulds,pressing to the end product.

Specification of Manual Decoiler Machine

| Model | MT-200 | MT-300 | MT-400 | MT-500 | MT-600 | MT-700 | MT-800 |

| Max.Coil Width | 200 mm | 300 mm | 400 mm | 500 mm | 600mm | 700mm | 800 mm |

| Coil Thickness | 0.1-3.2 mm | ||||||

| Coil I.D. | 450-530 mm | ||||||

| Coil O.D. | 1200 mm | ||||||

| Coil Weight | 500 kg | 800 kg | 1000 kg | 1500 kg | 2000kgs | 3000kgs | 3000 kg |

| Expansion | Manual Expanion | ||||||

| Pressing Arm | Optional | ||||||

| Power | 0.5 HP | 1 HP | 2 HP | 3 HP | |||

| Inverter | Without | ||||||

| Speed | 16 m/min | ||||||