Pallet Decoiler Machine

Applicable Material

Model No.: FU

Applications: Garment accessories and electric connectors Automatic production

Applicable Coil Width: 150mm

Applicable Coil Thickness: 0.1-1.6mm

Coil Outer Diameter: 800-1200mm

Speed: 24m/min

Brief Profile of Pallet Decoiler Machine

A pallet decoiler machine is a type of decoiler used in metalworking and steel processing operations to uncoil coils of relatively narrow, soft materials, such as sheet metal or strips. This machine is designed to be the most simple and easy to unload the coils.

Pallet decoiler machines are typically used in conjunction with high-speed press machines and feeders for producing terminal stampings, small electrical parts, metal button stampings, and eyelet stampings. The decoiler is capable of holding several coils with a width of less than 150mm and a thickness of less than 1.0mm, with a total weight of up to 2000kg.

One of the significant advantages of the pallet decoiler machine is its ability to accommodate all types of inner diameters, making it suitable for a range of different coil sizes. The feeding speed of this machine can reach up to 24m/min, making it ideal for small scale manufacturing applications requiring a continuous production flow.

Overall, pallet decoiler machines play a vital role in uncoiling metals, ensuring continuous production and reducing downtimes in manufacturing processes. They are simple and efficient tools for handling smaller coils of material in metalworking applications.

Application of Pallet Decoiler Machine

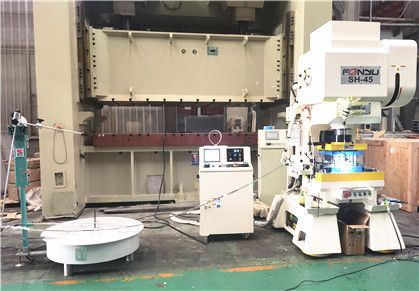

Usually, FU decoiler machine is working with high speed press machine.

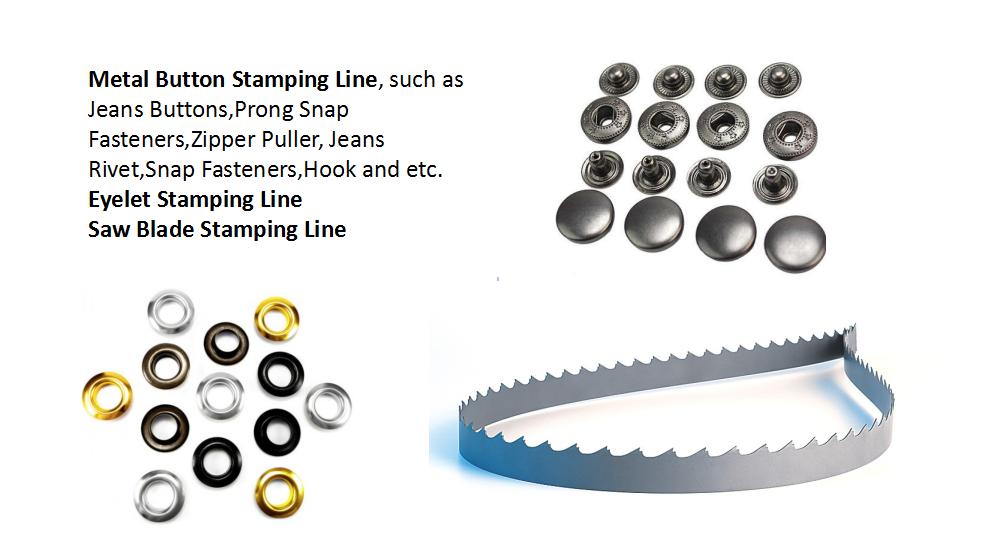

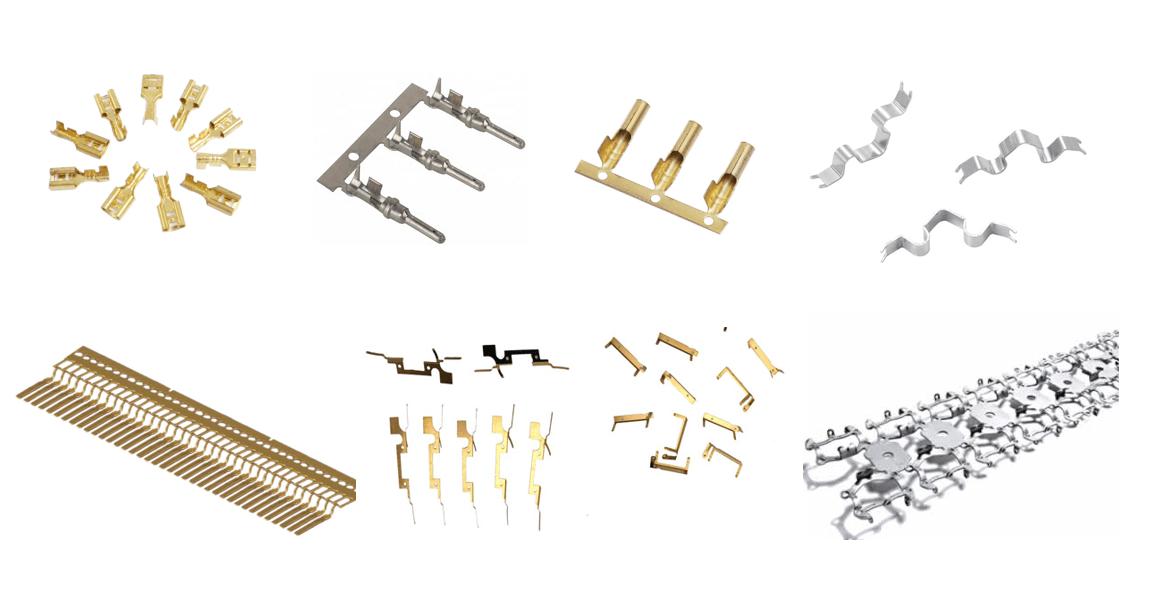

Pallet Decoiler machine Widely used in Garment accessories and electric connectors Automatic production such as metal button, eyelet, Led stand, terminal, saw blad, precision mobile phone accessories.

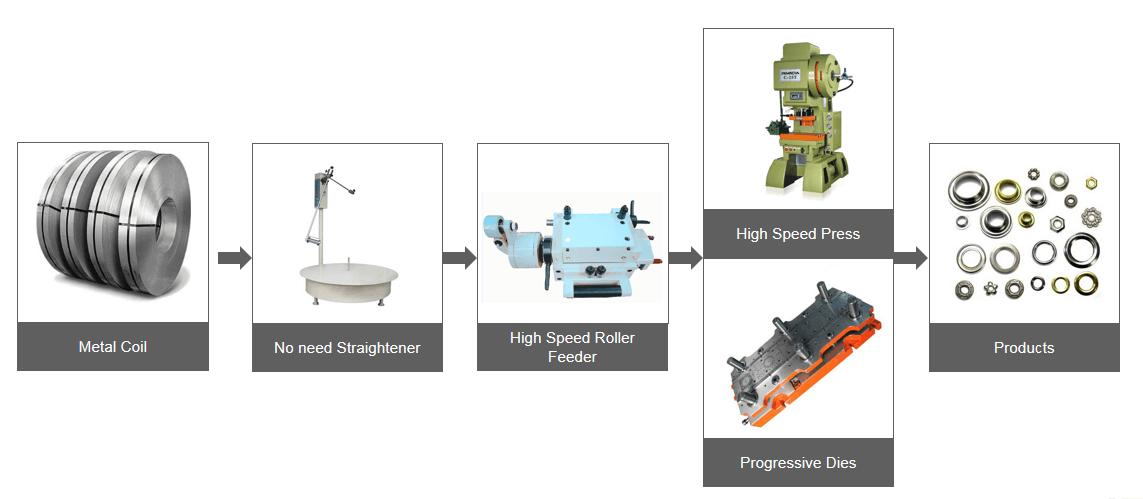

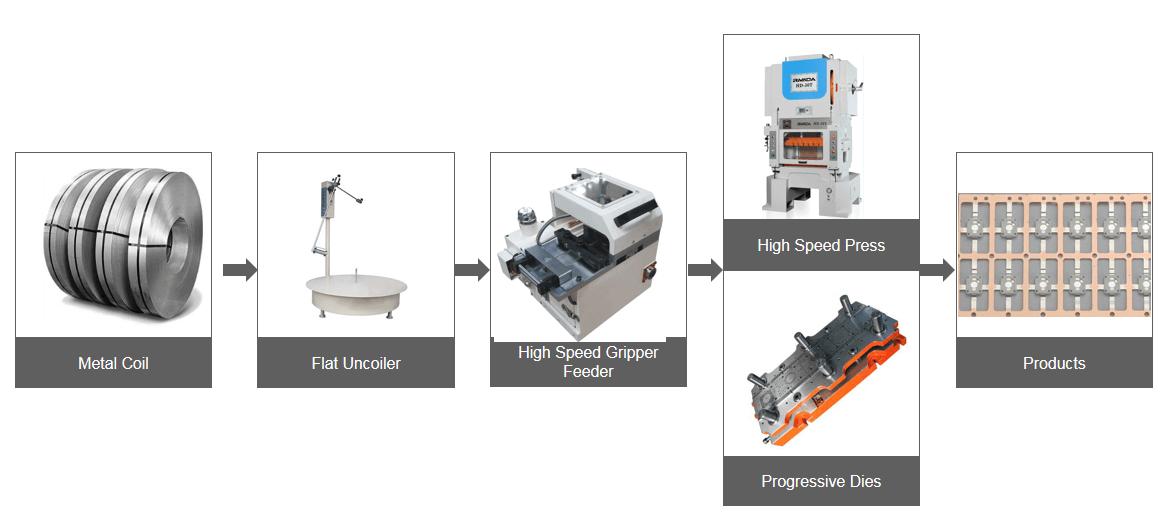

The configuration of High speed Metal button/eyelet/terminal/Saw blade stamping press machine.

Step-1: Pallet decoiler machine, Loading coil and uncoilling coils

Step-2: High speed Feeder machine, Feed coil to press machine.

Step-3: High speed press machine with the moulds,pressing to the end product.

The configuration of High speed press line for making electronic parts such terminal.

Step-1: Pallet Decoiler Machine, Loading coil and uncoilling coil.

Step-2: High speed Gripper feeder machine, Feed coil to press machine.

Step-3: High speed press machine with the moulds,pressing to the end product

Specification of Pallet Decoiler Machine

| Model | FU-500 | FU-1000 | FU-2000 |

| Max. Coil Width | 150 mm | ||

| Coil Thickness | 0.1 mm - 1.0 mm | ||

| Loading Weight | 500 kgs | 800 kgs | 1500 kgs |

| Max. Loading Height | 600 mm | ||

| Max. Coil O.D. | 800 mm | 1000 mm | 1200 mm |

| Feeding Speed | 24 m/min | ||

| Motor | 0.5 HP | 1 HP | 2 HP |

| Inverter | No | Delta, Taiwan | |

Video of Pallet Decoiler Machine