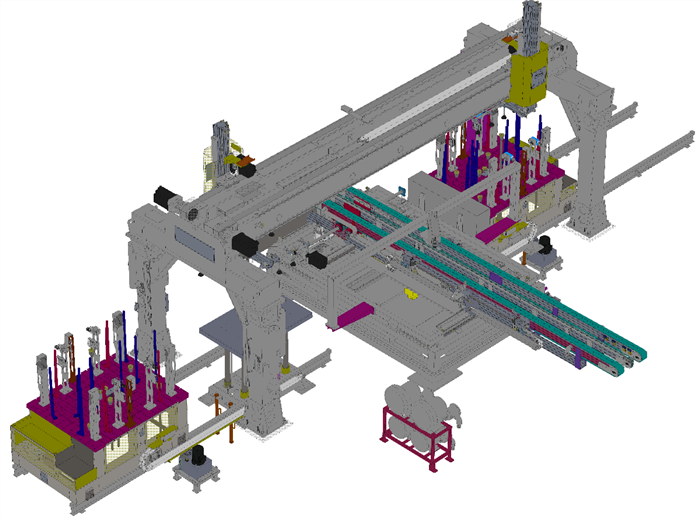

Destacker And Transfer System

A destacker and transfer system is a type of equipment used in industrial applications to automate the process of destacking and transferring materials or products from one location to another. It is commonly used in manufacturing and packaging operations where there is a need to handle large volumes of stacked materials efficiently.

The destacker component of the system is responsible for separating individual items from a stack or pile and positioning them for further processing or transfer. It typically uses mechanical or pneumatic mechanisms to lift, separate, and align the materials, ensuring a smooth and accurate transfer.

The transfer component of the system involves the movement of the destacked materials from one location to another. This can be achieved through various methods such as conveyor belts, robotic arms, or automated guided vehicles (AGVs). The transfer system ensures that the destacked materials are transported safely and precisely to their designated destination, whether it is a production line, packaging station, or storage area.Overall, the destacker and transfer system helps optimize productivity, reduce manual labor, improve efficiency, and minimize the risk of errors or damage during material handling processes.

What's the fuction of SUNRUI Destacker and transfer system?

The SUNRUI Destacker and transfer system is designed to automate the process of destacking and transferring materials or products from one location to another. Its main function is to efficiently handle large volumes of materials or products in industries such as packaging, food processing, and manufacturing.Here are the specific functions of the SUNRUI Destacker and transfer system:

Destacking:

The system is capable of destacking materials or products from a stack, such as pallets, trays, or containers. It uses automated mechanisms to separate individual items from the stack in a controlled manner.

Transfer:

Once the materials or products are destacked, the system transfers them to the desired location. This can involve moving them along conveyor belts, robotic arms, or other transfer mechanisms to transport them to the next stage of the production process or to their final destination.

Sorting and orientation:

The system may also include features to sort or orient the destacked items based on specific criteria. This can involve aligning them in a particular direction, segregating them based on size or type, or arranging them in a specific order for downstream processes.

Integration with other equipment:

The SUNRUI Destacker and transfer system can be integrated with other equipment or production lines, allowing for seamless material flow and coordination. This integration ensures that the destacked items are efficiently transferred to the next stage of the production process without disruptions.

Control and monitoring:

The system is equipped with sensors, control mechanisms, and software integration to ensure precise control and monitoring of the destacking and transfer processes. This allows for real-time tracking, adjustments, and ensures that the system operates at optimal efficiency.

Overall, the SUNRUI Destacker and transfer system automates the destacking and transfer of materials or products, streamlining production processes, improving efficiency, and reducing manual labor.

Why choose SUNRUI Destacker and transfer system?

Here are some reasons why one might choose SUNRUI Destacker and transfer system:

Increased productivity:

The automated system can handle destacking and transferring tasks at a faster rate compared to manual labor, leading to increased productivity and throughput.

Improved efficiency:

The system is designed to optimize material flow, reducing the time and effort required to move materials or products from one place to another. This helps in streamlining the overall production process.

Enhanced safety:

The automated system eliminates the need for manual handling of heavy or bulky materials, reducing the risk of injuries or accidents associated with manual labor.

Flexibility:

SUNRUI Destacker and transfer systems can be customized to meet specific requirements of different industries. They can handle a variety of materials, sizes, and shapes, making them versatile and adaptable to different production environments.

Cost-effective:

While the initial investment may be higher compared to manual labor, the long-term cost savings can be significant. The system reduces the need for a large workforce, lowers labor costs, and minimizes material wastage, resulting in overall cost savings.

Consistency and accuracy:

The automated system ensures consistent and accurate destacking and transfer processes, minimizing errors and improving quality control.

Overall, the SUNRUI Destacker and transfer system offers a reliable and efficient solution for businesses looking to streamline their material handling processes, improve productivity, and reduce costs.