NC Servo Feeder RNC-B RNC-H (0.4-4.5MM 0.6-6.0MM)

Applicable Material

Raw Material Type: Hot-Rolled Metal steel, Cold-Rolled Metal steel, Galvanized Metal steel, Stainless Steel etc.

Coil Width: 100-1300 mm

Material Thickness:

RNC-B 0.4-4.5mm

RNC-H 0.6-6.0mm

Yield Strength: ≤245 N/mm2

Tensile Strength: ≤392 N/mm2

Feeding pitch: 0-9999.99mm

Feeding Speed: 20m/min

Releasing Type: Pneumatic

PLC: Mitsubishi, Japan

Servo Motor and Driver: Mitsubishi, Japan/ Siemens, Germany

Driver: Mitsubishi, Japan

Touch Screen: WEINVIEW, Taiwan/ Mitsubishi, Japan

Function: Feeding The Coil Strips Into The Press Machine

Applications: Pressing Line/ Metal Stamping Line/ Forming Line

Brief Profile of NC Servo Feeder

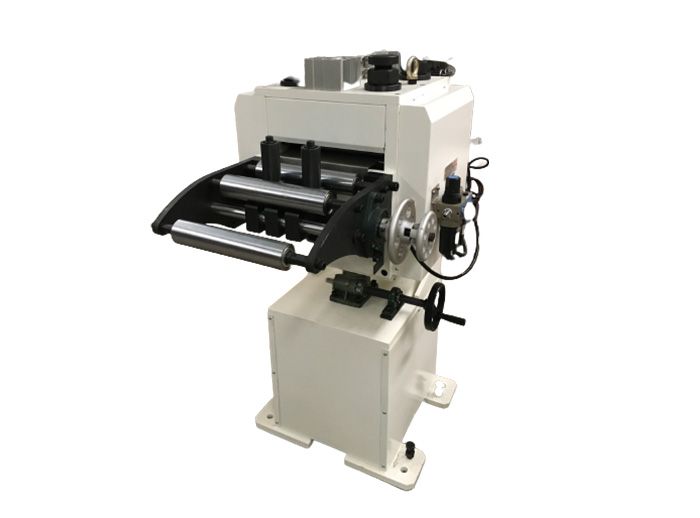

A servo feeder with pneumatic release for 0.4-4.5 and 0.6-6.0mm thickness is a type of feeding system used in metal stamping and punching machines. It is designed to accurately feed flat sheet metal blanks into the press or punching machine for further processing.

The system consists of several components, including a servo motor, pneumatic release system, and feeding rollers. The servo motor is responsible for controlling the feeding speed and accuracy, which ensures consistent feeding of the metal blanks into the machine. The pneumatic release system is responsible for holding the metal blanks in place during the feeding process until they are released into the press. The feeding rollers are responsible for pulling the metal blanks into the press with precision and speed.

The servo feeder with pneumatic release is suitable for processing metal sheets with a thickness range of 0.4-4.5 and 0.6-6.0mm . It is perfect for processing a range of materials such as aluminum, steel, and copper, among others.

The benefits of using a servo feeder with pneumatic release for 0.4-4.5 and 0.6-6.0mm thickness include high accuracy, reliability, and efficiency in the metalworking process. The precise control of the servo motor means that the metal blanks can be fed into the press with very high accuracy, reducing the chances of errors, and improving the overall quality of the final product. Moreover, the pneumatic release system ensures the rapid and smooth release of the metal blanks into the press, increasing the speed and productivity of the metalworking process.

Overall, the servo feeder with pneumatic release for 0.4-4.5 and 0.6-6.0mm thickness is a reliable and efficient tool in metalworking processes, especially in stamping and punching applications where accuracy and consistency are essential.

Application of NC Servo Feeder

NC servo feeder machine can be found in many different stamping product line such as hardware stamping line, saw blade stamping line, knives pressing line, motorcycle parts stamping line, car license plate stamping line, small auto parts stamping line, computer and electronic components stamping lines etc.

We have installed Press Feeders on all types of presses, all types of dies and possibly all types of raw materials like metal, non-metal, plastic, paper, foil, cloth available in coil form. And there are numerous cases when we installed feeders where the raw material available is in the form of strips.

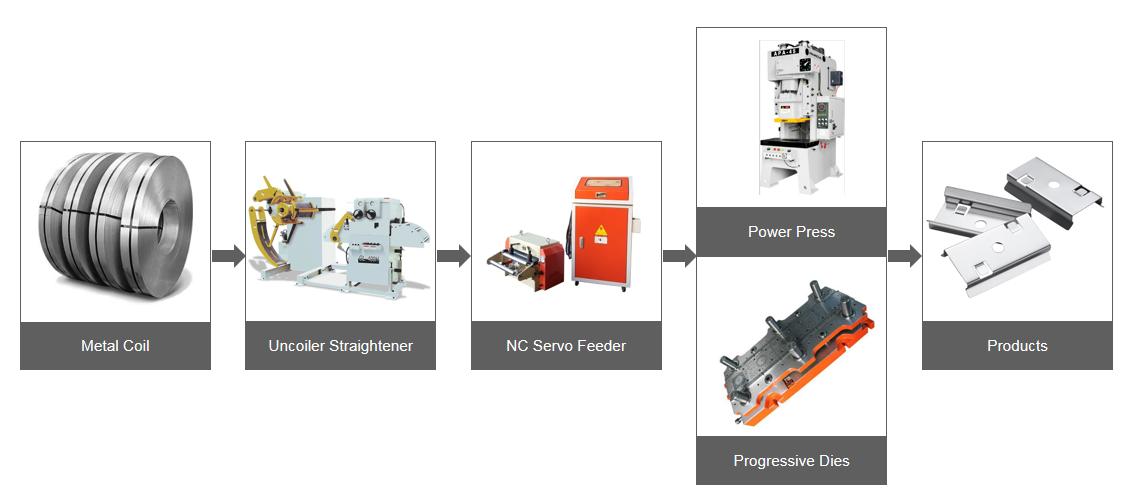

The configuration of metal sheet stamping line

Step-1: Decoiler straightener machine, Loading coil and uncoilling coil and straigthening the Coil strips.

Step-2: NC Servo Roll Feeder machine, Feed coil strips to press machine.

Step-3: Power pres machine with the moulds,pressing to the end product

Features of NC Servo Feeder

● Reliable Mechanical Design

Stabilized Steel frame construction make the quality of machine more reliable. High concentricity mechanical structure ensures better coil feeding performance, All rollers finished heat treated, hard chrome-plated, ground etc. After this craft, roller hardness comes HRC60-62°, Gear driven upper Roll with anti-backlash features to ensure non-slip, positive feeding.With shot blasting processing can be ensure the lifetime of machine and improve paint adhesion to keep the machine beautiful performace.

● Longer service life & lower maintenance cost

All main components come from worldwide famous brands with CE CERTIFICATION, good quality and safety, it can prolong the service life and lower maintenance cost such as full sets of Japanese low voltage components, Japan Mitsubishi PLC, Japan Yaskawa servo motor, etc.

● Advance and Smart control systems

Operating with Computerize Numerical Control by PLC program from internatioanl brand such as MITSUBISHI made in Japan, Siemens made in Germany and ABB made in Switzerland, it can ensure +/-0.01mm high feeding precision. Directly input the 20 difference feeding length on the control display screen and then it can reach needed feeding length, the Max. Feeding length is 9999.99mm.

● Accuracy and reliable feeding performance

High-precision drivers by utilizing the capabilities of high-resolution servo motors and servo drive with low inertia, ensures a reliable coil feeding accuracy.

Operating with Computerize Numerical Control by PLC program from MITSUBISHI made in Japan, it can ensure +/-0.1mm high feeding precision.

Directly input the 20 difference feeding length on the control display screen and then it can reach needed feeding length, the Max. Feeding length is 9999.99mm.

Specification of NC Servo Feeder

| Model | RNC-300B | RNC-400B | RNC-500B | RNC-600B | RNC-300H | RNC-400H | RNC-500H |

| Coil Width | 300 mm | 400 mm | 500 mm | 600 mm | 300 mm | 400 mm | 500 mm |

| Strip Thickness | 0.5-4.5 mm | 0.5-6.0mm | |||||

| Release | Pneumatic Type Releasing System | ||||||

| Feed Roll | Upper Roll Ø75mm, Bottom Roll Ø90mm | Upper Roll Ø90mm, Bottom Roll Ø90mm | |||||

| Feed Length | Max. 9999.99 mm | ||||||

| Speed | Max. 20m/min | ||||||

| Accuracy | ± 0.1 mm | ||||||

| Servo Motor | Yaskawa, Japan | ||||||

| Servo Drive | Yaskawa, Japan | ||||||

| PLC | Mitsubishi, Japan | ||||||

| Touch Screen | Weinview, Taiwan | ||||||

| Power | 1.3 Kw | 1.8 Kw | 2.9 Kw | 1.8 Kw | 2.9 Kw | ||

Video of NC Servo Feeder