Zigzag Servo Feeder

Applicable Material

Raw Material Type: Hot-Rolled Metal steel, Cold-Rolled Metal steel, Galvanized Metal steel, Stainless Steel etc.

Coil Width: 100-1300 mm

Material Thickness: 0.3-3.2mm

Yield Strength: ≤245 N/mm2

Tensile Strength: ≤392 N/mm2

Feeding pitch: 0-9999.99mm

Feeding Speed: 20m/min

Releasing Type: Pneumatic

PLC: Mitsubishi, Japan

Servo Motor and Driver: Mitsubishi, Japan/ Siemens, Germany

Driver: Mitsubishi, Japan

Touch Screen: WEINVIEW, Taiwan/ Mitsubishi, Japan

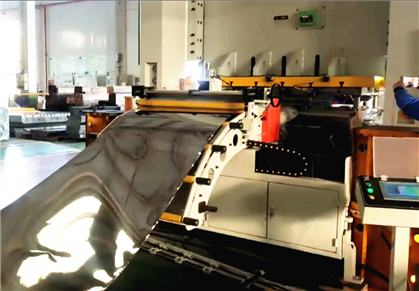

Function: Feeding The Coil Strips Into The Press Machine

Applications: Pressing Line/ Metal Stamping Line/ Forming Line

Brief Profile of Zigzag Servo Feeder

The zigzag servo feeder machine is a highly efficient and advanced feeding system that is designed to meet the demands of modern metalworking processes. It boasts a range of features that make it highly effective at processing a wide range of metals and materials, including coil materials.

The machine is driven by an AC servo motor that is connected to a precision gear train. This ensures that the feeding process is highly accurate and consistent, reducing the risk of errors and increasing the overall quality of the finished product. The lateral travel of the feed and material is powered by a combination AC servo motor and linear ball screw, allowing for simultaneous or sequential delivery of the material in X-Y movement.

One of the most significant advantages of the zigzag servo feeder machine is its ability to provide up to 22% material savings. By staggering the feeding of parts in a ZigZag Press Feed System, the machine can boost productivity, reduce material waste, and save time and money.

The machine is operator-friendly, thanks to its easy-to-use control system, which automatically calculates and sets up all the machine parameters quickly and accurately. The control also automatically calculates the optimum movement in each axis, providing fast and easy setup in a single or dual-axis format.

The ServoMatic and ServoMax Servo Press Feeds can either be press-mounted or cabinet-mounted, depending on the specific requirements of the production line. Additionally, the SMX H and H6 Servo Roll Feeds are cabinet-mounted.

Overall, the zigzag servo feeder machine is a highly efficient and reliable feeding system that offers significant productivity advantages in stagger feeding. It is a perfect solution for modern metalworking processes that require high accuracy, efficiency, and material savings.

Application of Zigzag Servo Feeder

This zigzag NC servo feeder production line is suitable for lamps, ceiling lamps, eletric cooker, pot, tea class punching, stainless steel tableware, water pump, water heater , bearing retainer, fire extinguisher, filter and accumulator, motor stator, rotor, motor shell electronic, the refrigerator compressor, air conditioner compressor casing , auto clutch, car pulley, automobile wheel Hub, brake disc stamping.

The configuration of Circle Stamping line

Step-1: Decoiler Straightener machine, Loading coil and uncoilling coil and straigthening the Coil strips.

Step-2: Zigzag NC Feeder machine, Feed coil strips to press machine.

Step-3: Power pres machine with the moulds,pressing to the end product

Specification of Zigzag Servo Feeder

| Model | NCP-200 | NCP-300 | NCP-400 | NCP-500 | NCP-600 | NCP-800 |

| Coil Width | 200 mm | 300 mm | 400 mm | 500 mm | 600 mm | 800 mm |

| Strip Thickness | 0.2-2.0 mm | |||||

| Release | Pneumatic Type Releasing System | |||||

| Roll Pressure | Spring Type | |||||

| Feed Roll | Upper Roll 1pc, Bottom Roll 1pc | |||||

| Feed Length | Max. 9999.99 mm | |||||

| Speed | Feeding Speed Max. 20 m/min, Zigzag Movement Speed Max. 30 m/min | |||||

| Left Center Displacement | 100 mm | 150 mm | 200 mm | 250 mm | 300 mm | 400 mm |

| Accuracy | ± 0.1 mm | |||||

| Servo Motor | Yaskawa, Japan | |||||

| Servo Drive | Yaskawa, Japan | |||||

| PLC | Mitsubishi, Japan | |||||

| Touch Screen | Weinview, Taiwan | |||||

Video of Zigzag Servo Feeder