Double Crank H Frame Press Machine

Applicable Material

Material Type: Suitable for vary kind of coil material, such as Galvanized steel, Stainless steel, CR Steel, HR Steel, Galvanized steel, Stainless steel,Aluminum, Cooper etc.

Capacity: 160ton to 600ton

PLC control.

Dry clutch or Wet clutch for optional.

Hydraulic overload protected.

Both mechanical and electric cam control.

Auto lubricated.

Customized bigger table better for big sheet stamping or progressive die stamping process.

Light curtain, inverter,air cushion are optional.

Brief Profile of Double Crank H Frame Press Machine

The Double Crank H Frame Press Machine, also known as a double crank power press, is a large industrial machine used for heavy-duty metal forming operations. This type of press features an H-shaped frame and is designed to provide high precision and stability during operation.

The press uses two cranks, one on each side of the H-frame, to power the ram which delivers a powerful force to shape the metal. The double crank mechanism allows for greater control during the pressing process, making the machine ideal for precision metal forming operations.

The Double Crank H Frame Press Machine is commonly used in various industries such as automotive, aerospace, and manufacturing. It can handle a variety of metal-forming operations, including stamping, drawing, perforating, bending, and pressing.

The machine can be operated using a clutch and brake system, which engages and disengages the crank mechanism, allowing operators to control the speed and power of the ram. The press also features a variety of safety features such as emergency stop buttons, safety guards and sensors to ensure operator safety during operation.

The Double Crank H Frame Press Machine is known for its ability to produce accurate and consistent results with high productivity rates, making it a popular choice for organizations looking to improve their metal-forming processes.

Application of Double Crank H Frame Press Machine

Double crank H Frame press machine is suitable for all kinds of metal sheet stamping, including the hardware parts, home appliances, furniture hardware, motorcycle accessories, mobile phone accessories, computer accessories and so on.

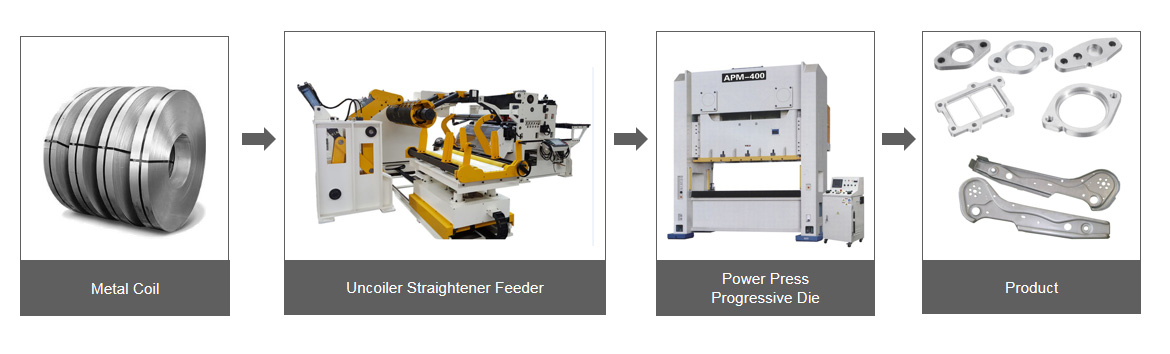

The configuration of metal sheet stamping line.

Step-1: Compact Straightener feeder machine, Loading coil and uncoilling coil strips and level and feed the strips into press machine.

Step-2: Power press machine with the progressive die, pressing to the end product.

Features of Double Crank H Frame Press Machine

● Steel welded body, tempering treatment, high rigidity, accuracy and stability, low integrated clearance, small changing in mold height.

● Small deviation of dynamic center, the mold life in large scale, small transfiguration for press.

● The crankshaft undergoes grinding treatment after high frequency quenching.

● The transmission gear is spur gear, the tooth surface is quenched and heat treated by medium frequency, with high transmission accuracy, high meshing accuracy, smooth transmission, large bearing capacity, strong gear strength, low noise and other advantages. Ensure reliable lubrication.

● Synchronous transmission system is a set of gear system connected by the main gear, to ensure the synchronous transmission machine drive shaft operation and slider movement synchronization, so as to ensure the synchronization of control signal and slider movement.

● The slide block adopts super-long eight-side guide rail with high guiding accuracy and good wear resistance. The gap of guide rail can be adjusted by push-pull bolt. The slide block guide board is made of copper-nickel alloy.

● The slider is equipped with hydraulic overload protection device, gas-liquid type, overload response will be generated when the rated tonnage is about 5%, and the slider will automatically stop when the alarm is given. After overload, the pressure recovery time is less than 3 minutes, and the manual unloading knob is set.

● The structure is strong enough to support the weight of the machine and the vibration generated by the punch press.

● High precision processing, high efficiency operation, machine to ensure products of high quality.

● Facilitate the operation of implementation, fixed locking type six-surface guide way, cutting low-noise, safe and reliable operating state.

Specification

| Model | APM-160 | APM-200 | APM-250 | APM-300 | |||||

| S | H | S | H | S | H | S | H | ||

| Capacity | Ton | 160 | 200 | 250 | 300 | ||||

| Rated tonnage point | mm | 6 | 3 | 6 | 3 | 7 | 3 | 7 | 3 |

| Stroke length | mm | 200 | 130 | 250 | 150 | 280 | 170 | 300 | 170 |

| Sroke per minute variable | s.p.m | 30-55 | 40-85 | 20-50 | 35-70 | 20-40 | 30-60 | 20-35 | 30-50 |

| Die height | mm | 450 | 400 | 500 | 450 | 550 | 450 | 550 | 450 |

| Slide adjustment | mm | 100 | 120 | 120 | 120 | ||||

| Slide area | mm | 1600x650x70 | 1850x750x95 | 2300x900x95 | 2400x900x95 | ||||

| Bolster area | mm | 1800x760x150 | 2200x940x170 | 2500x1000x170 | 2500x1000x190 | ||||

| Slide opening | mm | 700x450 | 900x600 | 900x600 | 1000x600 | ||||

| Main motor | kwxp | 15x4 | 18.5x4 | 22x4 | 30x4 | ||||

| Slide adjustment motor | kwxp | 1x4 | 1x4 | 2x4 | 2x4 | ||||

| Air pessure | kg/㎡ | 6 | 6 | 6 | 6 | ||||

| precision | GB/JIS 1class | GB/JIS 1class | GB/JIS 1class | GB/JIS 1class | |||||

| Max.upper die weight | kg | 1200 | 1500 | 2000 | 2000 | ||||

| Die Cushion capacity | Ton | 6.3x2 | 10x2 | 14x2 | 14x2 | ||||

| Model | APM-400 | APM-500 | APM-600 | ||||

| S | H | S | H | S | H | ||

| Capacity | Ton | 400 | 500 | 600 | |||

| Rated tonnage point | mm | 7 | 3 | 10 | 12 | ||

| Stroke length | mm | 300 | 170 | 350 | 300 | 350 | 300 |

| Sroke per minute variable | s.p.m | 20-35 | 20-40 | 15-25 | 20-35 | 15-25 | 20-30 |

| Die height | mm | 550 | 450 | 600 | 550 | 700 | 600 |

| Slide adjustment | mm | 120 | 120 | 150 | |||

| Slide area | mm | A 2500x1000x95 | A 2600x1100x100 | 3400x1100x110 | |||

| B 3000x1000x95 | B 3200x1100x100 | ||||||

| C 3200x1000x95 | |||||||

| Bolster area | mm | A 2700x1100x190 | A 2800x1200x220 | 3600x1200x230 | |||

| B 3200x1100x190 | B 3400x1200x220 | ||||||

| C 3400x1100x190 | |||||||

| Slide opening | mm | 1100x600 | A 1100x600 | 1100x800 | |||

| B 1100x600 | |||||||

| Main motor | kwxp | 37x4 | 45x4 | 55x4 | |||

| Slide adjustment motor | kwxp | 2x4 | 3.7x4 | 5x4 | |||

| Air pessure | kg/㎡ | 6 | 6 | 6 | |||

| precision | GB/JIS 1class | GB/JIS 1class | GB/JIS 1class | ||||

| Max.upper die weight | kg | A | 2400 | 4000 | 6000 | ||

| B | |||||||

| C | 3200 | 4000 | 6000 | ||||

| D | |||||||

| Die Cushion capacity | Ton | 14x2 | |||||