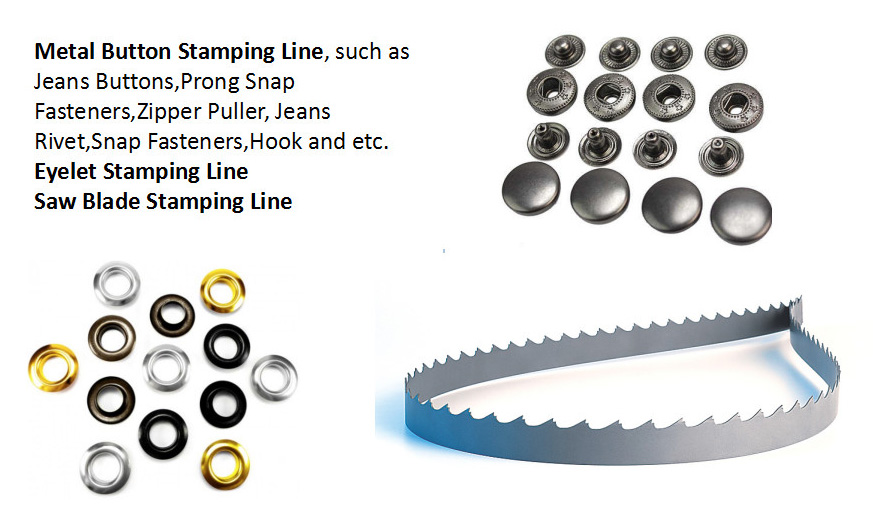

High Speed Metal Button Stamping Line

With the rise of raw materials and the increase of labor costs, the

traditional metal button stamping processing method has been unable to meet the

needs of clients.

So SunRui machine recommend this High Speed metal button stamping line and now is the common line used in the garment accessories industry.

There are many kinds of metal buttons such as Jean buttons, Prong Snap, Fasteners, Zipper Puller, Jean Rivet, Snap Fasteners, Hooks, Eyelet and so on.

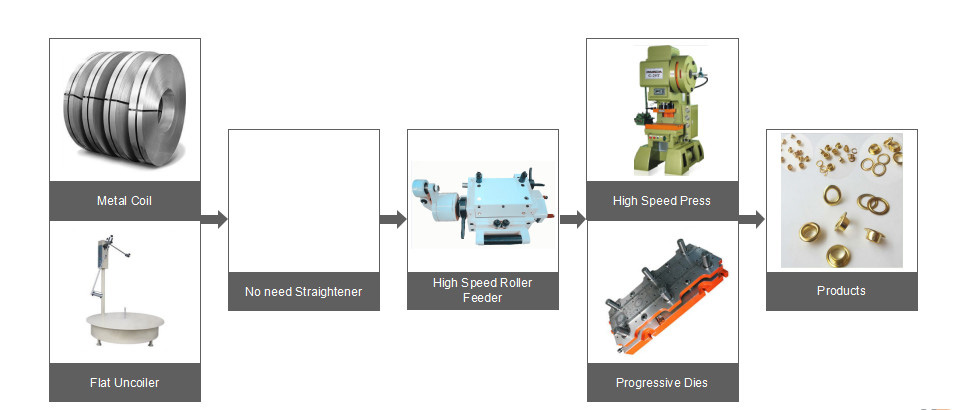

Here with High speed metal button production line configuration for your reference.

Step-1: Decoiler machine, Loading coil and uncoilling coil.

Step-2: High Speed Roll Feeder machine, Feed coil strips to press machine.

Step-3: High Speed Press Machine with the moulds,pressing to the end product.

Main Machine

Flat Decoiler FU-1000

Suitable raw material: Cooper, brass, iron, steel etc.

Yield Strength: ≤245 N/mm2

Coil Width: 100 mm

Material Thickness: 0.1-1.0 mm

Coil outer diameter: 800mm

Max. Loading weight: 1000kg

Working speed: 0-24m/min

High Speed Roll Feeder Machine, RF-105NS

Suitable raw material: Cooper, brass, iron, steel etc.

Yield Strength: ≤245 N/mm2

Coil Width: 100 mm

Feeding length: 0-50mm

Material Thickness: 0-1.6 mm

Working speed: 0-16m/min

High Speed Press Machine, RC-25

Suitable raw material: Cooper, brass, iron, steel etc.

Yield Strength: ≤245 N/mm2

Tonnage capacity: 25ton

Stroke of slide: 30mm

Speed(SPM): 200-800SPM

Die-height(mm): 180-210mm

Slide adjustment(mm): 30mm

Why we recommend you 3 rows or 5 rows per punch?

1. For long development, it can save materials and increase productivity and efficiency.

For this proposal - equipped with RC-25 , so we recommend 3 rows for client.

The customer has too many types metal buttons should be stamped, which is requires lots of progressive dies, so the high productivity and highly cost effective progressive dies are the best choose to fit the high speed metal button stamping punching line.

The high speed press machine capacity is 200-900/min, and the Min. output capacity per min is 600pcs. Half time will be saved during the operation compared with the normal press punching line.

2.Our high speed press machine equipped the dynamic balancing device, it can make the machine steady when it works and prolong the service life of equipment.

What's more, with the water tank device, it can protect the progressive die from be broken. The function of water tank is cooling the dies and reduce the wastage of the dies.

3. We helped one of Bangladesh client to build up a new metal button company who bought 9 set of high speed production lines, 65 sets of progressive dies and 23 sets of assembly machine. So we do have capacity to provide you the best machine and best service.

If you need the whole line,please kindly send me the drawing of the metal buttons.

We will provide the whole line according to your requirements.