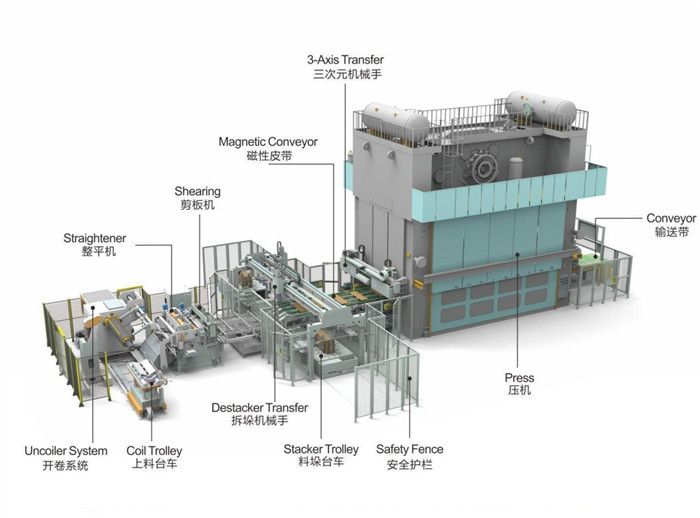

Destacker and 3D transfer system with coil feed line

SUNRUI Destacker and 3D transfer system with coil feed line is an efficient manufacturing system that consists of the following main components:

Compact coil feed line

Hydraulic shearing machine

Destacker with Magnetic Conveyor

3-axis transfer system

Stamping press machine

Product end conveyor

What is the destacker and 3D transfer system with coil feed line offered by SUNRUI?

SUNRUI destacker and 3D transfer system with coil feed line is a combination of machinery used in the manufacturing industry to automate the process of feeding and transferring materials for further processing. This integrated solution improves efficiency, productivity, and accuracy in the manufacturing process.

The system consists of a coil feed line, destacker, and 3D transfer system.

The coil feed line feeds continuous coil material into the production line, ensuring a steady supply of material. The destacker separates and feeds individual sheets or parts from a stack of material, while the 3D transfer system picks up and transfers the materials in three dimensions (X, Y, and Z axes). Together, these components work in harmony to automate material handling and feeding processes. Coil Feed Line: A coil feed line is a system that feeds continuous coil material, such as metal coils, into the production line.

It typically includes components like decoilers, straighteners, and feeders, which work together to unwind, straighten, and feed the material in a controlled manner.

Destacker: A destacker is a machine designed to separate and feed individual sheets or parts from a stack of material. It typically uses vacuum or mechanical means to lift and separate the top sheet from the stack and then feeds it to downstream equipment.

3D Transfer System: A 3D transfer system consists of transfer tools or robots that can move in three dimensions (X, Y, and Z axes). These transfer tools are used to pick up, move, and position components or parts during the manufacturing process. The 3D movement capability allows for precise and flexible handling of the materials.

When combined, the destacker, 3D transfer system, and coil feed line form an integrated solution for automating material handling and feeding processes in manufacturing. The destacker separates and feeds individual sheets or parts, which are then picked up and transferred by the 3D transfer system. The coil feed line ensures a steady supply of material by feeding continuous coil material into the production line. This integrated system improves efficiency, productivity, and accuracy in the manufacturing process.

The working process of Destacker and 3D transfer system with coil feed line

First, the metal coil is loaded onto the decoiler, which unwinds the coil in a controlled manner. Then, the straightener eliminates any distortions or deformations in the metal coil by applying pressure and bending it to straighten it. Theened coil is then fed into the feeder, which ensures precise and consistent feeding. From there, the metal coil enters the cutting machine, where it is sheared or cut into desired lengths or shapes.

During the cutting process, the destacker removes individual coils from a stack, and the 3D transfer system accurately positions and transfers the coils at various stations within the system. This ensures the coils are precisely placed for further processing or handling. The system repeats this process for each metal coil, allowing for continuous and efficient production.

Coil Loading: The metal coil is loaded onto the decoiler, which is equipped with a motorized spindle. The decoiler unwinds the coil in a controlled manner, ensuring proper tension and feeding.

Straightening: The metal coil then passes through the straightener, which consists of a series of adjustable rollers. These rollers apply pressure and bend the coil to straighten it, eliminating any distortions or deformations.

Feeding: The straightened metal coil is then fed into the feeder, which ensures precise and consistent feeding. The feeder controls the positioning and speed of the coil, preparing it for the cutting operation.

Cutting: The metal coil enters the cutting machine, where it is sheared or cut into desired lengths or shapes. The cutting machine may employ different methods such as shearing, punching, or laser cutting, depending on the specific requirements of the application.

Destacking and 3D Transfer: As the cutting process is carried out, the destacker removes individual coils from a stack, and the 3D transfer system works in conjunction to accurately position and transfer the coils at various stations within the system. This ensures the coils are precisely placed for further processing or handling.

Repeat Process: The system repeats the process for each metal coil, allowing for continuous and efficient production.

Throughout the entire process, the compact decoiler straightener feeder and cutting machine with destacker and 3D transfer system operates in a synchronized and automated manner. It eliminates manual labor, improves productivity, and ensures consistent and high-quality output in metal processing operations.

What are the advantages of SUNRUI destacker and 3D transfer system with coil feed line?

SUNRUI destacker and 3D transfer systems offer several advantages:

Increased Efficiency: These systems automate the process of separating and feeding materials, reducing manual labor and improving overall production efficiency.

Improved Productivity: By providing a continuous and reliable supply of material, the destacker and coil feed line of downstream equipment, such as presses or assembly lines.

Versatility: These systems can handle a wide range of materials and sizes, making them suitable for various industries and applications.

Precision and Accuracy: The 3D transfer system allows for precise positioning and movement of components, ensuring accuracy in the manufacturing process. This helps maintain consistent quality and reduces waste.

Reduced Downtime: The automated operation and integration with other equipment minimize downtime and enable continuous production.

Safety: Advanced safety features and mechanisms ensure the safety of operators and prevent accidents. Flexibility: Some destacker and 3D transfer systems offer customization options to meet specific production requirements, allowing for greater flexibility in manufacturing processes.

Cost Savings: By optimizing material handling and streamlining production processes, these systems can lead to cost savings in terms of labor, material waste, and increased productivity. It is always recommended to refer to the manufacturer's specifications and customer reviews to understand the specific advantages and features of SUNRUI destacker and 3D transfer systems.

The main parts of SUNRUI destacker and 3D transfer system with coil feed line

The compact coil feed line and cutting machine with destacker and 3D transfer system is a comprehensive solution for handling, straightening, feeding, and cutting metal coils in a compact and space-saving manner.

This system combines multiple functions into one integrated unit to optimize efficiency and productivity in metal processing operations. Here is a breakdown of each component:

Decoiler: This component is responsible for unwinding and feeding the metal coil into the system. It typically features a motorized spindle that unwinds the coil in a controlled manner to ensure proper tension and feeding.

Straightener: The straightener is designed to eliminate any material distortions or deformations that may exist in the metal coil. It consists of a series of adjustable rollers that apply and bend the coil to straighten it before further processing.

Feeder: The feeder is responsible for accurately and consistently feeding the straightened metal coil into the cutting machine or other processing equipment. It ensures precise positioning and controlled feeding speed to optimize the cutting or processing operation.

Cutting machine: The cutting machine is used to shear or cut the metal coil into desired lengths or shapes. It may employ different cutting methods, such as shearing, punching, or laser cutting, depending on the specific requirements of the application.

Destacker and 3D transfer system: These components work together to handle and position the metal coils within the system. The destacker removes individual coils from a stack, and the 3D transfer system allows for precise movement and positioning of the coils, ensuring accurate placement at various stations within the system.

The compact design of this system allows for efficient use of space, making it suitable for manufacturers with limited floor space. It offers a streamlined and automated solution for metal processing, reducing manual labor, improving productivity, and ensuring and high-quality output. It is commonly used in industries such as automotive, appliances, and metal fabrication where space optimization and efficient coil handling are crucial.

Destacker and 3D transfer system with coil feed line video