High Speed Gripper Feed line

Applicable material

Raw material: Brass, Copper, Stainless Steel, Iron

Material Thickness: 0.1-1.6m

Coil width: 20-200mm

High Speed Gripper Feed Lines configuration

Pallet Decoiler, FU

High Speed Gripper feeder, GS-906

High Speed Press Machine, RH

Progressive(For optional)

Unwinder machine(For optional)

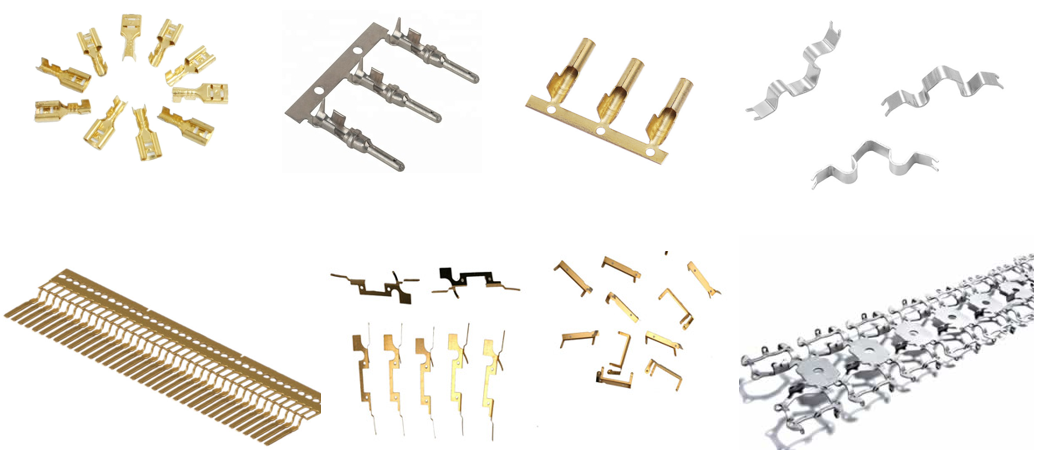

High Speed Gripper Feed line ideal for the mass production of parts such as connectors,terminal, and other electronic components

The High Speed Gripper Feed Line is designed to handle high-speed, high-volume production of critical metal-stamped components. It is ideal for the mass production of parts such as connectors, wire terminal products, spring terminal block, power-line terminal and terminal assembly, and other electronic components. The system can achieve high throughput rates, precise accuracy, and fast die changeover times, making it highly efficient.

It can feed the coil strips thickness from 0.1 to 1.5mm,and the feeding stroke up to 1200SPM.

In summary, the High Speed Gripper Feed Line is a sophisticated production system that enables manufacturers to produce large quantities of precision stamped parts quickly and efficiently. It is widely used in industries that require high-volume, accurate stamping operations, such as automotive, aerospace, and electronics manufacturing.

The Stamped Parts Produced By High Speed Gripper Feed line

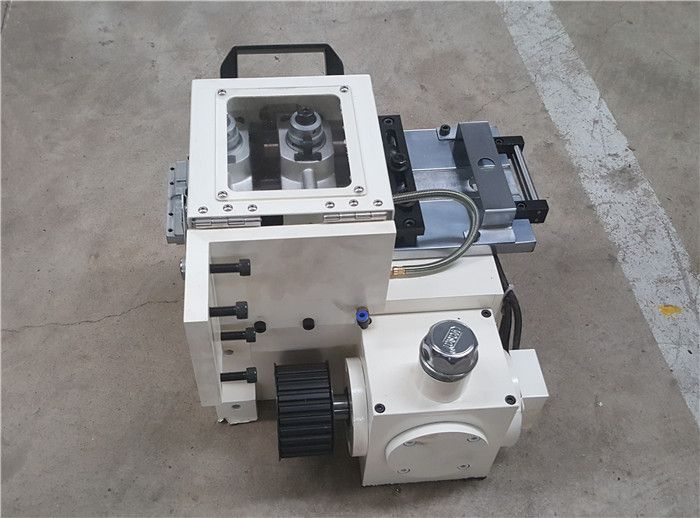

Main Machines Of High Speed Gripper Feed line

Pallet Decoiler, FU

1. Pallet Decoiler is suitable for various kinds of metal sheet coil with thin thickness, such as brass, coopper, stainless steel, iron and so on.

2. Our pallet decoiler machine is made by welded steel which is capable of 4 or 5 coils at the same time and it can save coil changing time.

3. The speed is 0-24m/min, with inverter for speed control.

High Speed Gripper feeder, GS-906

1. High speed gripper feeder machine is customized for small electric parts,such as all kinds of wire terminal products, spring terminal block, power-line terminal and terminal assembly.

2. It can feed the coil strips thickness from 0.1 to 1.5mm,and the feeding stroke up to 1200SPM.

High Speed Press Machine, RH

1. Machine body is high strength cast iron,Best stably.

2. Adopt Double guide pillar, Four guide column structure.

3. Zero error Germany FAG ball bearing.

4. Dynamic equilibrium for choosing.

5. Machine include hydraulic locking,Die Height Indicator, 1 Set tool, motor-driven adjustable die.Cooling machine etc.

6. Man-machine interface is microcomputer controlling.

7. Lubrication system is forceful automation.

Ternimal Progressive die

1. Terminal progressive die in the stamping process material material strips always moves in one direction, the progressive die is a multi-task sequential die. In a pair of die, it can include punching, bending and stretching, and many other processes. It has high productivity, usually with 1,2,3,5,6 and 7 rows output accroding to the the size of terminal and production requirements and raw material saving as well.

2. The general configuration is pallet decoiler machine, high speed gripper feeder machine, H frame high speed press machine and eyelet progress die, the speed line can reach 500SPM.

Video of High Speed Gripper Feed line